- Date

Akash Shirsath (KIT) showcases the accuracy of DETCHEM PBR with comparisons to 3D Particle Resolved CFD at ISCRE 28

omegadot

Akash Shirsath from KIT presented at the ISCRE 28 conference, showcasing DETCHEM's built-in heat transfer capabilities. In his talk, Akash compared DETCHEM PBR simulation results against DETCHEM DUO Particle Resolved CFD (PRCFD). PBR results were nearly as accurate as PRCFD but required only seconds instead of days to obtain results.

Akash Shirsath presented his study, “Modeling of catalytic fixed-bed reactors: comparison of 1D and 3D particle-resolved simulations,” at the 28th International Symposium on Chemical Reaction Engineering (ISCRE) in Turku, Finland on June 17, 2024. This presentation showcased how DETCHEM PBR’s built-in heat transfer correlations can model reactor temperature and composition profiles that are effectively similar to computationally intensive 3D Particle Resolved CFD (PRCFD). Instead of requiring days or weeks to obtain results, PBR often requires a few seconds to run.

This presentation reviewed the most comprehensive study undertaken to-date to validate DETCHEM PBR against PRCFD. Forty-eight PRCFD runs, each requiring at least a day to complete on a high-performance computer (HPC) using hundreds of cores, supplied the validation data set. The full set of test conditions spanned different chemistries, particle sizes, flow rates and thermal boundary conditions.

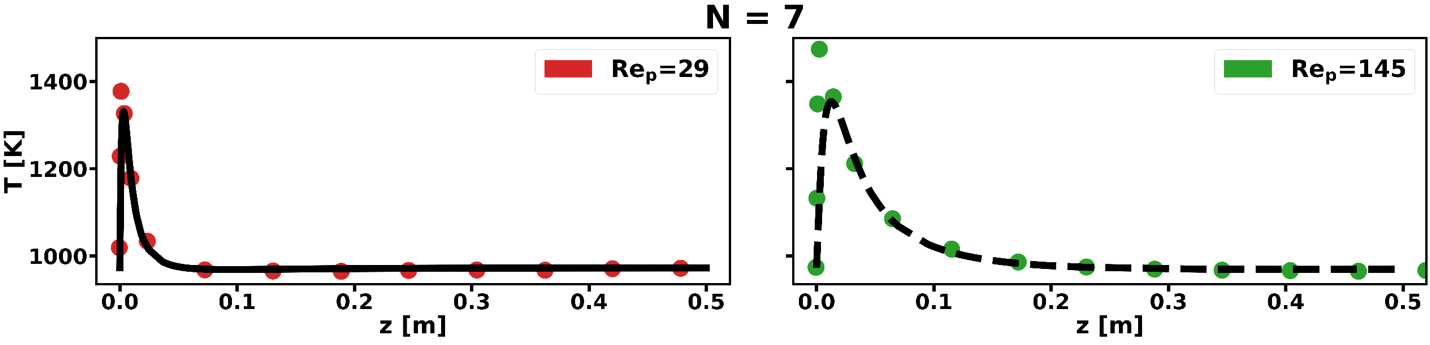

As shown in the representative figure below for the non-isothermal, non-adiabatic simulation of the Catalytic Partial Oxidation (CPOX) of Methane, DETHCEM PBR produced results that are nearly as accurate as PRCFD.

DETCHEM PBR’s impressive capabilities are available to help solve your fixed bed reactor challenges. Move faster. Contact omegadot for more information.

Comparison of axial temperature profiles with DETCHEM PBR (lines) and 3D PRCFD (symbols) for the Catalytic Partial

Oxidation (CPOX) of Methane. Results for two flow rates (particle Reynolds numbers) are shown. In both cases, the bed is

0.5 m long, containing 6,000 particles, with a tube:particle diameter ratio of 7.

Comparison of axial temperature profiles with DETCHEM PBR (lines) and 3D PRCFD (symbols) for the Catalytic Partial

Oxidation (CPOX) of Methane. Results for two flow rates (particle Reynolds numbers) are shown. In both cases, the bed is

0.5 m long, containing 6,000 particles, with a tube:particle diameter ratio of 7.